Introduction to Industrial Linear Slides

Introduction to Industrial Linear Slides

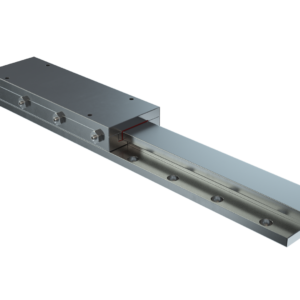

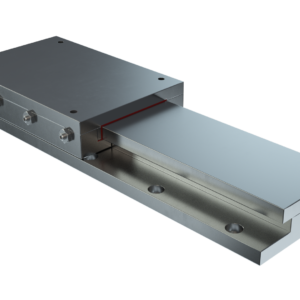

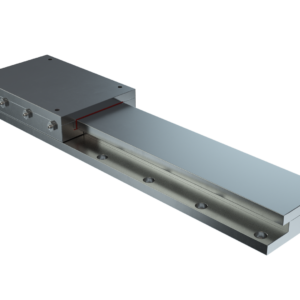

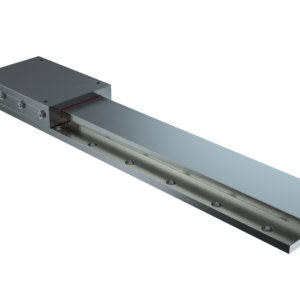

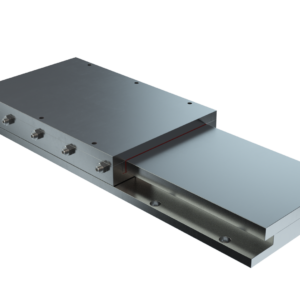

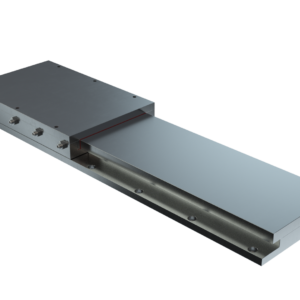

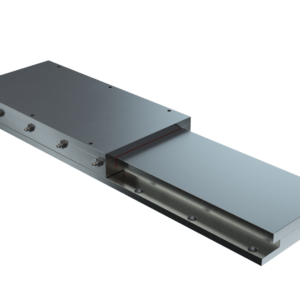

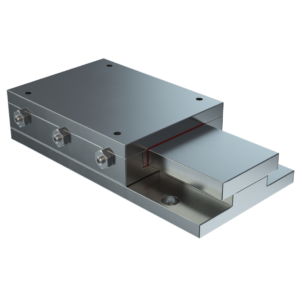

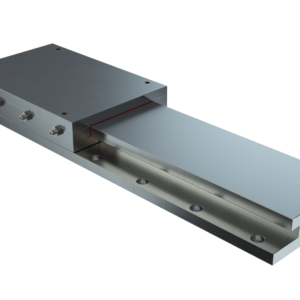

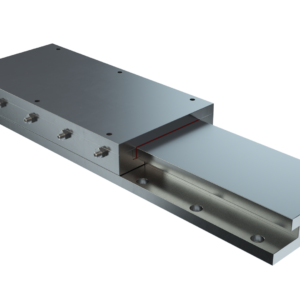

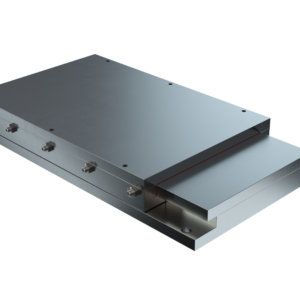

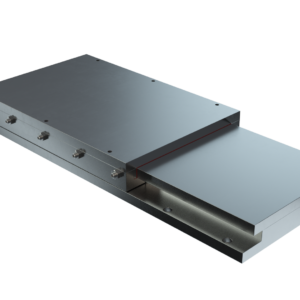

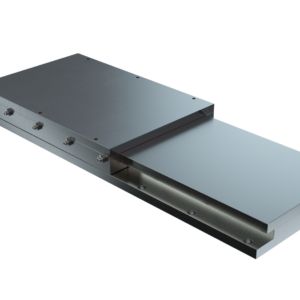

- The saddle supports the payload put in motion. Sometimes the moving portion of the system rests on top of the saddle, and other times it is connected to the side or bottom of the saddle.

- The base is the counterpart to the saddle. In normal configurations, the saddle of the linear slide is affixed to moving portions of the machinery, while the base is connected to a stationary object. However, slides can be inverted and affixed in the opposite configuration.

The purpose of all linear slides is to limit motion to a straight line, and to reduce friction between moving parts of machine systems. Some linear slides reduce friction through ball bearings or roller bearings, while others involve a surface coating (like Rulon®) that eliminates metal-to-metal contact.

Types of Linear Slides

Ball Bearing/ Roller Bearing Slides

Some of the most common linear slides rely on ball bearings or roller bearings to reduce friction. These bearings are held in pockets between the carriage and the base, and reduce friction by eliminating opposing linear forces. Ball and roller bearings transfer linear friction into rotational friction, which requires much less force to overcome. Ball and roller bearing slides are relatively simple to produce and to maintain, often requiring very little external lubrication to provide precise motion. However, they are unable to support heavy payloads due to the bearings’ tendency to deform or break under excessive stress. These types of linear slides are also not ideal for harsh factory environments, as contamination from dust or debris can lead to slide failure.

Plain Bearing Slides

In contrast to ball bearing and roller bearing slides, plain bearing slides do not contain a rolling element. To reduce friction, they rely on lubrication or special coatings instead of spherical or cylindrical bearings. Because of their simplicity, plain bearing slides are often easier to maintain and can withstand more harsh environments than ball/ roller bearing slides. The three main types of plain bearing slides are square gib slides, dovetail slides and plain bushings.

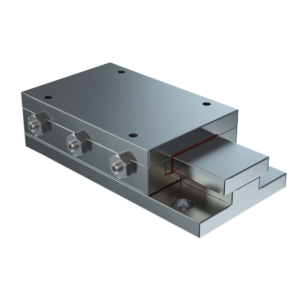

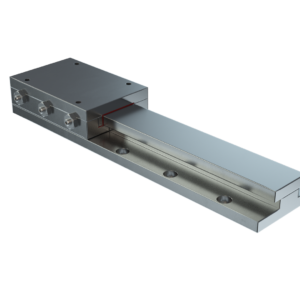

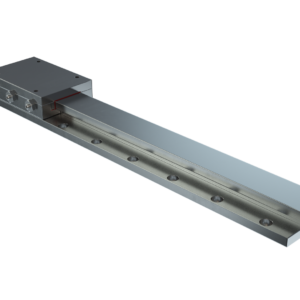

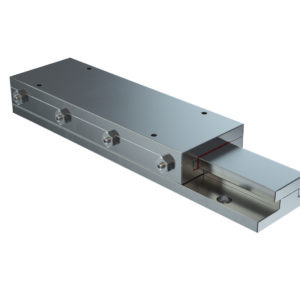

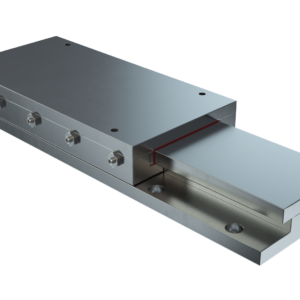

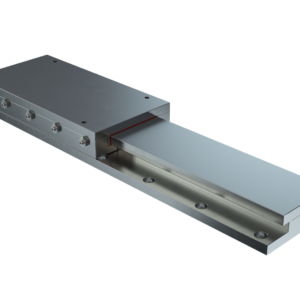

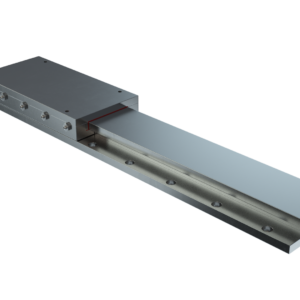

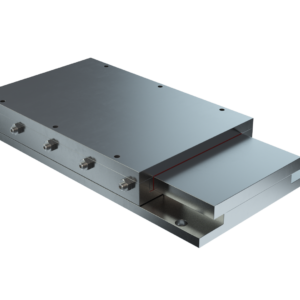

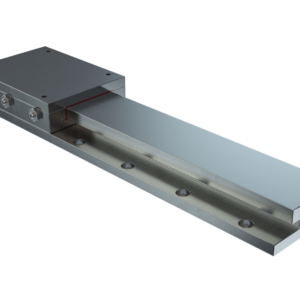

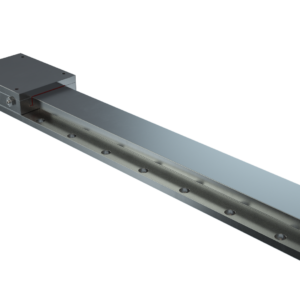

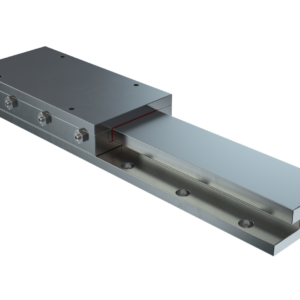

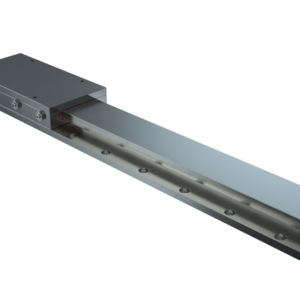

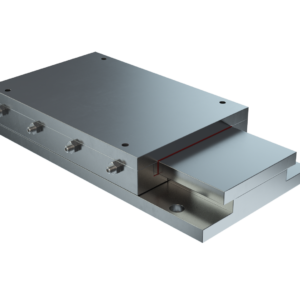

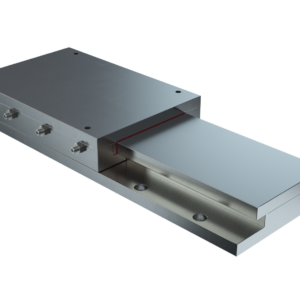

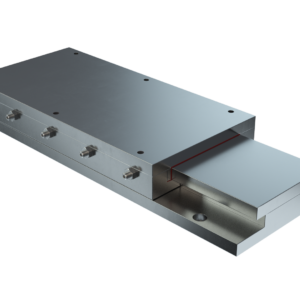

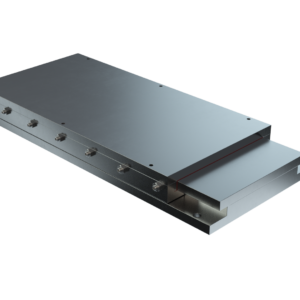

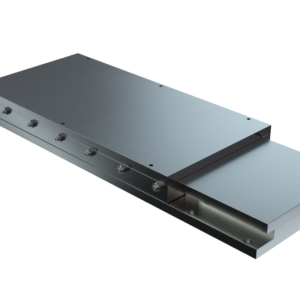

Square Gib Slides, also known as Box Gib or Boxway Slides

Square gib linear slides, or boxway slides, feature a T-shaped protrusion from the saddle that fits in a rectangular groove on the base. The assembly can be effectively locked in place, preventing motion beyond two linear directions. The primary advantage of square gib slides is their ability to withstand the heaviest payloads compared to the size of the slide. Because of their design, square gib slides are able to share the force of the payload between their X and Y directions, allowing for both heavier loads and more flexible installations. When manufactured with a PTFE coating, such as Rulon®, they also require little or no lubrication to function smoothly and efficiently. However, manufacturing is key in determining the quality of a square gib slide, as the high degree of surface contact requires extreme precision for both the saddle and the base.

Dovetail slides

Another common type of plain bearing linear slide is a Dovetail slide. These slide assemblies involve a V-shaped protrusion on the saddle that fits into a corresponding slot on the base. Similar to square gib slides, these two elements can be interlocked to prevent non-linear motion. Dovetail slides generally handle heavier loads than ball bearing or roller bearing slides, but not as heavy as boxway slides because they involve less surface area in contact between the saddle and the base. Forces from the load act on the slide at acute angles (often 45, 55 or 60 degrees) instead of 90 degrees, making deformation a possibility at high weight levels. Still, dovetail slides can have similar advantages in low maintenance and lasting performance if properly coated.

Cylindrical Column Slides

While functionally similar to square gib and dovetail slides, cylindrical column slides feature a completely different profile. Instead of a tongue-and-groove design to lock the saddle to the base, cylindrical column slides feature a base with cylindrical rails and a saddle with corresponding circular holes. The surface of the saddle that touches the rails is often referred to as a “bushing.” Cylindrical column slides’ main advantage is their flexibility in terms of materials. Bushings can be made from nearly any alloy, as well as plastics, so they can be designed to function in varying environments, including abrasive chemicals, dust and debris. Compared to ball or roller bearing slides, cylindrical column slides are better able to distribute loads because they create a point line of contact between the bushing and rail. Still, cylindrical column slides lack the stiffness and strength of square gib and dovetail slides, and so cannot be used in many heavy-duty operations.

The Toughest Industrial Linear Slides with the Highest Load Capacities

Every application requiring linear motion will call for slides with different specifications. Simple ball-bearing slides work great for dresser drawers and light duty automation, while dovetail and square gib slides are required for heavier industrial, machining and general manufacturing applications. For long-lasting performance in tough industrial environments requiring heavy payloads, square gib slides are often the best choice. Their construction and shape make them the stiffest and strongest of all linear slide types. Compared to dovetail slides, square gib slides can support heavier payloads by distributing weight efficiently between both X and Y directions. Square gib slides are also ideal for applications requiring short, repetitive motion such as spring coiling. When ball or roller bearings fail to fully rotate during a cycle, either bearing deflection or brinelling can occur. Square gib slides support the payload with their full length, no matter how short the cycle of motion. Square gib slides can also be coated with Rulon®, a PTFE-based substance that provides long-lasting friction reduction while minimizing corrosion and “slip/stick” errors. Quality industrial linear slide manufacturers know that Rulon® coatings out-perform other slide coatings, and significantly reduce friction between the saddle and the ways while requiring little or no lubrication during use. Furthermore, the physical properties of the coating serve to dampen vibrations, which can lead to more precise motion and overall longevity for machine systems. Like other plain bearing slides, square gib slides continue to function flawlessly even in harsh manufacturing environments. When correctly manufactured and installed, their contact surfaces are impervious to dust, debris and even chemical abrasion. DuraBond offers precision-machined square gib linear slides in a variety of stock sizes, as well as custom types of linear slides. Browse our industrial linear slides below, or contact us with any questions.

Every application requiring linear motion will call for slides with different specifications. Simple ball-bearing slides work great for dresser drawers and light duty automation, while dovetail and square gib slides are required for heavier industrial, machining and general manufacturing applications. For long-lasting performance in tough industrial environments requiring heavy payloads, square gib slides are often the best choice. Their construction and shape make them the stiffest and strongest of all linear slide types. Compared to dovetail slides, square gib slides can support heavier payloads by distributing weight efficiently between both X and Y directions. Square gib slides are also ideal for applications requiring short, repetitive motion such as spring coiling. When ball or roller bearings fail to fully rotate during a cycle, either bearing deflection or brinelling can occur. Square gib slides support the payload with their full length, no matter how short the cycle of motion. Square gib slides can also be coated with Rulon®, a PTFE-based substance that provides long-lasting friction reduction while minimizing corrosion and “slip/stick” errors. Quality industrial linear slide manufacturers know that Rulon® coatings out-perform other slide coatings, and significantly reduce friction between the saddle and the ways while requiring little or no lubrication during use. Furthermore, the physical properties of the coating serve to dampen vibrations, which can lead to more precise motion and overall longevity for machine systems. Like other plain bearing slides, square gib slides continue to function flawlessly even in harsh manufacturing environments. When correctly manufactured and installed, their contact surfaces are impervious to dust, debris and even chemical abrasion. DuraBond offers precision-machined square gib linear slides in a variety of stock sizes, as well as custom types of linear slides. Browse our industrial linear slides below, or contact us with any questions.

Shop Online

2" Width Slides

4" Width Slides

9" Width Slides

3" Width Slides

6" Width Slides

12" Width Slides

Contact DuraBond

If you have comments or questions or would like to request a custom linear slide quote, please contact us through the form.

5627 Airline Highway

Fruitport, MI 49415

1-800-933-0404