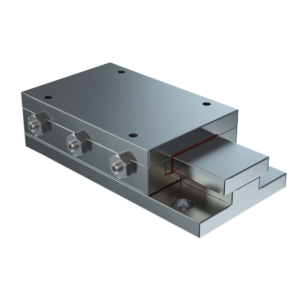

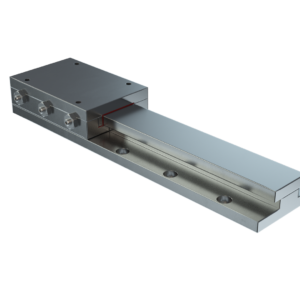

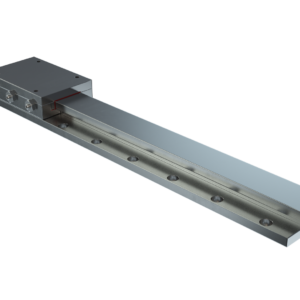

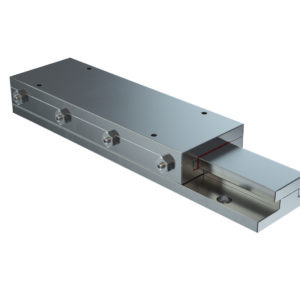

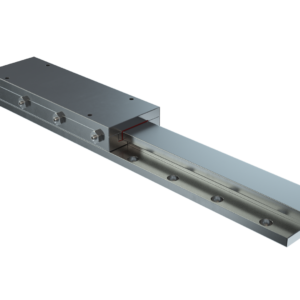

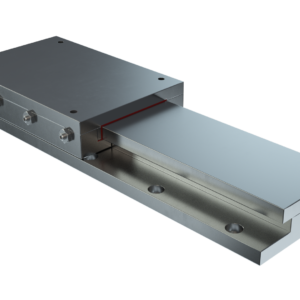

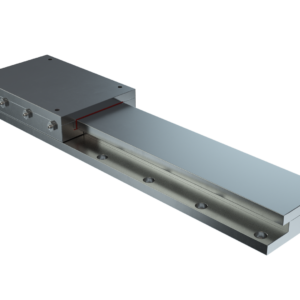

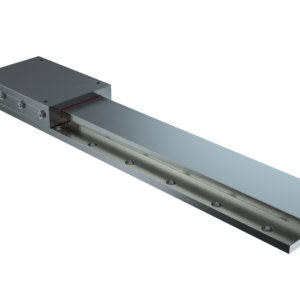

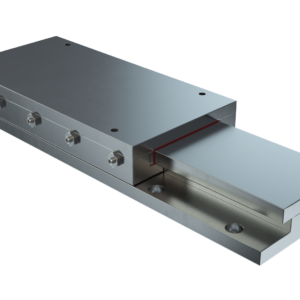

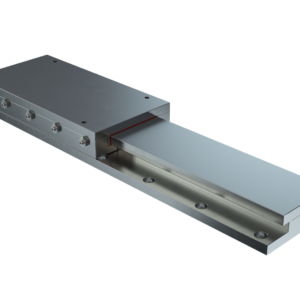

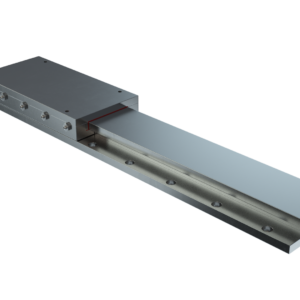

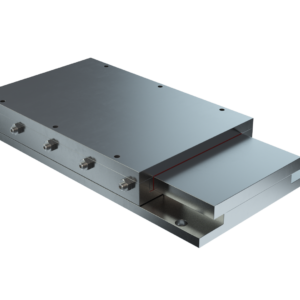

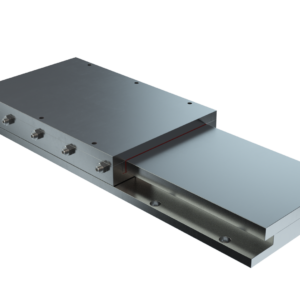

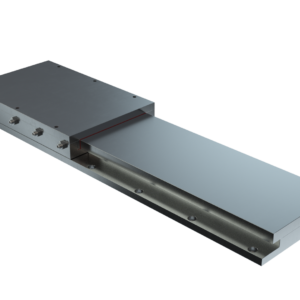

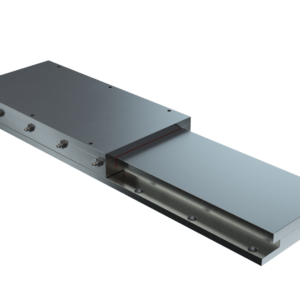

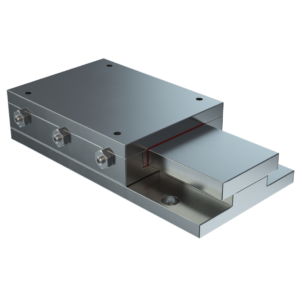

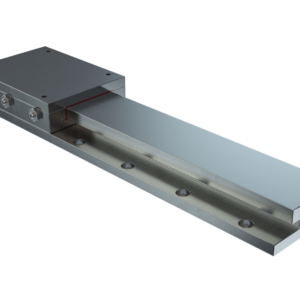

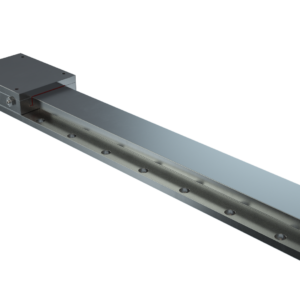

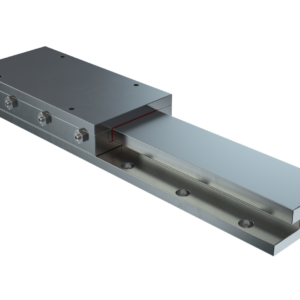

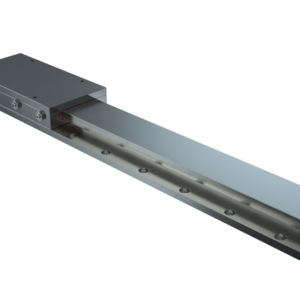

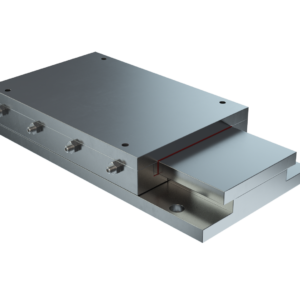

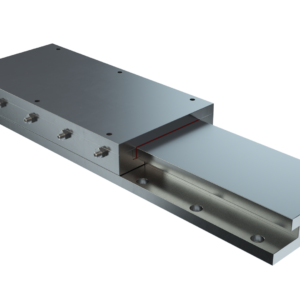

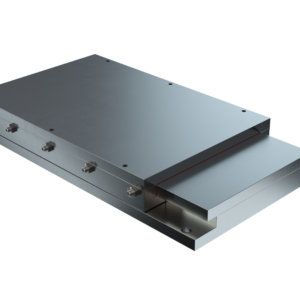

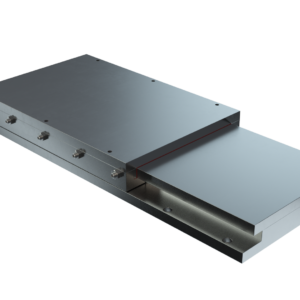

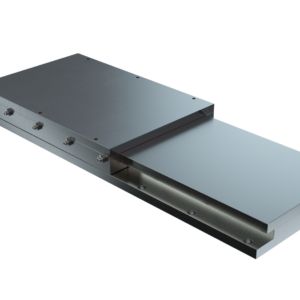

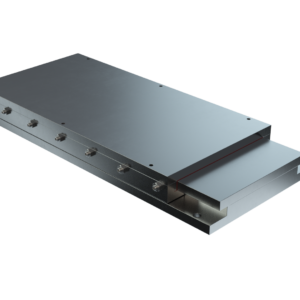

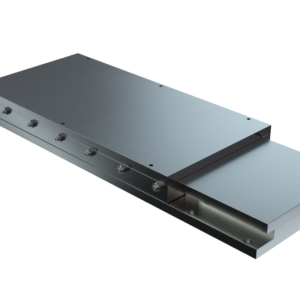

DuraBond Industrial Linear Slides

Our heavy duty, industrial linear slides are designed to perform in harsh factory environments, where other linear slides would fail due to load capacity, surface wear or heat tolerance.

Features of Our Linear Slides:

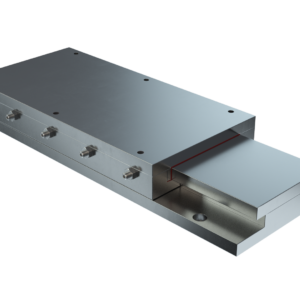

- Dry operation: DuraBond slides work without lubrication

- Rulon coating: an ideal coating to reduce friction, improve longevity and maintain durability

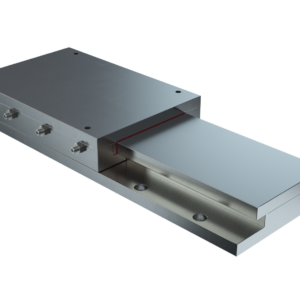

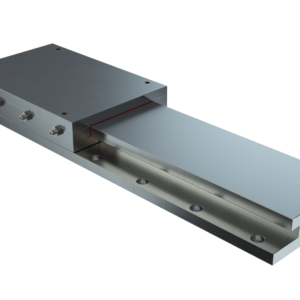

- Box-gib (square-gib) design: improves load-bearing capacity and makes minute adjustments and customization easier than other slide designs

- Exceptional tolerance to heat and cold: DuraBond linear slides are rated to operate smoothly between -400 and 550 degrees F.

- Corrosion resistance: Durabond slides can perform in corrosive environments and under conditions of high and low humidity, or where high vacuums are present

- Vibration dampening: Durabond slides’ steel construction and box-gib design provide an effect of dampening vibrations from equipment. This can improve overall equipment longevity.

Rulon® Coating

Rulon is a wear and friction-control coating owned by Saint-Gobain Seals. The PTFE coating is ideal for reducing friction between the saddle and base of our linear slides. We affix Rulon to the saddle through a proprietary bonding process, perfected over years and resulting in a strong bond that you can trust throughout the life of the slide.

Comparing Durabond Linear Slides to Other Slide Types

DuraBond Slides vs Dovetail Slides

DuraBond’s box gib slides offer higher load capacities by increasing surface area interfacing between the saddle and the base. Dovetail slides also absorb loads at acute angles, whereas box gib slides absorb loads at 90-degree angles. This further improves DuraBond slides’ ability to resist deforming under heavy loads..

DuraBond Slides vs Ball Bearing Slides

Under force, ball and roller bearings deform easily, rendering the slide apparatus useless. Even hardened steel bearings are susceptible to deformation, and most bearing slides also require external lubrication. While roller bearing and ball bearing slides are ideal for light-duty applications and long-travel slides, our industrial-strength square gib slides are able to out-perform and out-last ball bearing slides in highly demanding environments.

For more information on how DuraBond’s square gib design compares to other linear slide types, visitor our Introduction to Linear Slides page

Comparing Durabond Linear Slides to Other Slide Types

Our experienced engineering staff machines each slide from billet, grinding every surface to extremely close tolerances. We then apply the Rulon® coating through a proprietary epoxying process that yields a strong bond, and we further grind the coating down to an ideal thickness that provides rigidity, durability and nearly frictionless linear motion.

To learn more about our design specifications and tolerances, visit our Design Specifications page

Visit our Applications page to learn more about the industries that make use of our heavy duty, industrial linear slides.

Shop Online

2" Width Slides

4" Width Slides

9" Width Slides

3" Width Slides

6" Width Slides

12" Width Slides

Contact DuraBond

If you have comments or questions or would like to request a custom linear slide quote, please contact us through the form.

5627 Airline Highway

Fruitport, MI 49415

1-800-933-0404